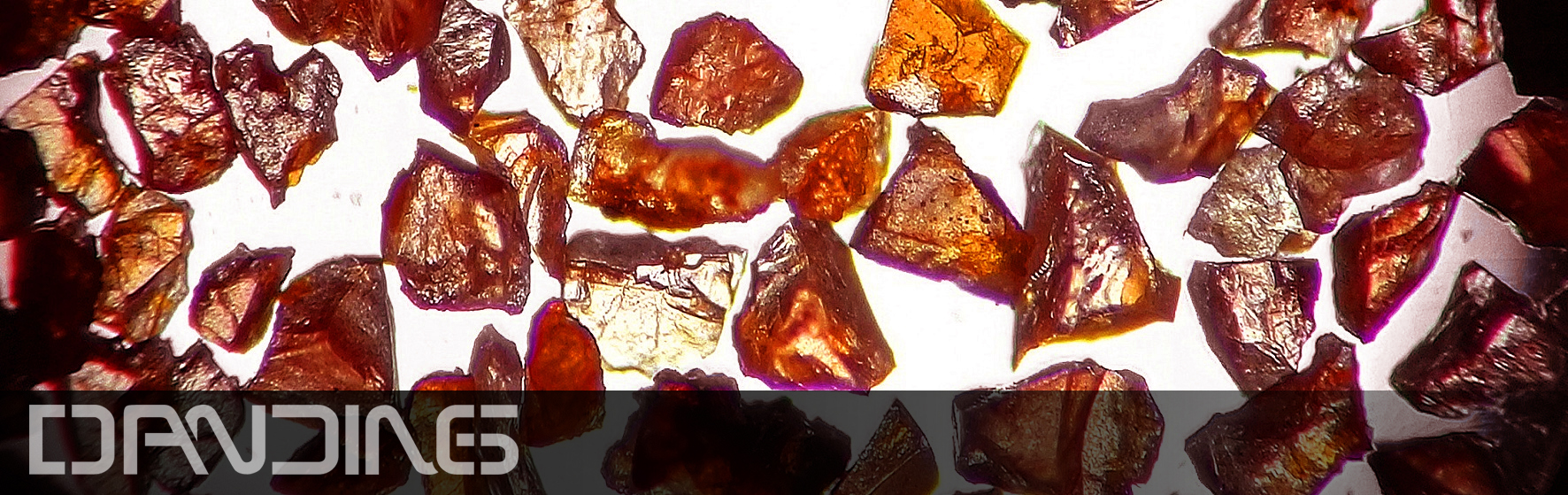

Garnet is one of natural abrasive instead of synthetic. It is an industrial gemstone that free of embedment, which makes excellent for coating adhesion, as well as applications where low or no transfer of grit into the substrate can be tolerated. Garnet is used for dry and wet blast operations both and comes in a wide variety of types and sizes.

DANDING GARNET ABRASIVE (D-GTE) is a sandblasting mineral, derived from owned almandine mining. No matter ROCK GARNET or ALLUVIAL GARNET are all appropriate for wet and dry sandblasting applications both. "Efficient and Clean" should be the best descriptions for D-GTE.

D-GTE is kind of cost-effective abrasive which would last a long time with the Mohs harness 8.0;

D-GTE is recyclable abrasive for a number of times cause its superior toughness and low friability;

D-GTE is environmentally friendly abrasive;

D-GTE is nontoxic abrasive with low free silica content (≤1%);

D-GTE is low dusting material;

D-GTE is excellent material for surface preparation because the characteristic embedment, troughs, and peaks free.

GARNET BLAST ABRASIVE MATERIAL (D-GTE) is widely used in shipbuilding and maintaining industries. DANDING blast media can handle weld seams and construction damage easy and efficient when blasting. Multiple water-washing and sieving gave the grains low dust levels which improve working conditions and productivity in tanks, voids and confined spaces. D-GTE is suitable for variety blasting surfaces: carbon steel, stainless steel, alumina, copper and all other alloys cause its metallic iron free characteristic.

D-GTE is a high performance, general purpose blasting media for petrochemical applications like tanks, offshore platforms, pipe racks, pipeline projects and so on. Great performance provides garnet grains higher cutting speed and lower material consumption than other blast media. The efficient and durable D-GTE not only completed turnaround jobs in short time but also reduce costly plant downtime.

D-GTE could be used in blast rooms when complete non-ferrous abrasive media is necessary. Garnet grains are used in aluminum surfaces,sensitive substrates or installed electromagnetic components preclude the use of metal abrasives.

D-GTE also has excellent performance in heavy equipment applications like construction overhaul, military vehicle and other machineries.

D-GTE is a high performance, maintenance grade blasting abrasive that delivers the most efficient and cost-effective blast cleaning for construction surfaces that have heavy rust or thick coatings.

DANDING ALLUVIAL GARNET ABRASIVEis uncrushed with naturally rounded shape. Comparing with angular D-GTE abrasive material, this one could highly improve the finished products’ abrasion performance and causing lesser damage to denim.

Low dusting abrasive needs: tanks and other confined spaces;

Water contamination concern: dry docks, Bridges, Shipyards, etc;

Carbon steel, stainless steel, alumina, copper and all other alloys;

Powder coating, denim blasting;

Industrial painting.

is used for repair and maintenance purposes: weathered paint, rust, mill scale removing, and other coatings from surfaces of stainless steel, carbon steel, aluminum parts and etc.

is used for new steel, light paint, rust removal and special maintenance applications requiring reduced profiles.

is applicable for light blasting requiring a clean surface and minimum anchor profile including brush-off blast or high-pressure water blast system.

is also available for aluminum and fiberglass, as well as for rust removal and mill scale on new steel.

Luoyang Dan Ding Import And Export Trading Co.,Ltd

Room 7 - 2001, Shen-Tai New Century Plaza, Jiu Du Street,Luo Yang,471000,China.

Tel.: (86) 379 6222 3799 Fax : (86) 379 6222 3799

E-mail: info@lyddtc.com.