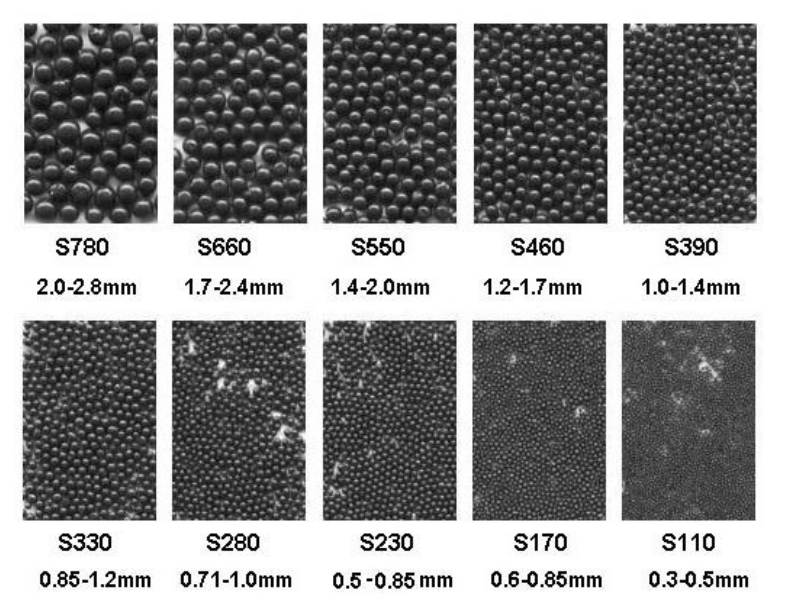

is the most widely used process for cleaning, stripping and improving a metal surface. The grade or size of steel shot will determine the ultimate finish achieved on the surface of the metal.

The round ball shape of the steel shot produces a clean, smooth and polished surface through a peening action created by the acceleration of the shot.

Smaller steel shot will result in a smoother and more polished surface. Larger shot will clean more aggressively but produce a rougher surface. Both air powered and wheel blast systems can be used to accelerate the steel shot onto the surface of the part.

Due to the hardness and density of steel shot, it can be recycled as much as 3000 times before eplacement. Since steel shot does not use an abrasive process, a minimal amount of dust is created in the blasting process.

is ideal for aggressive cleaning applications. It will quickly strip many types of surface contaminants from steel and other foundry metals.

| Item | Steel Grit | |

| Chemical Composition | C | 0.85-1.20 |

| Si | 0.40-1.20 | |

| Mn | 0.60-1.20 | |

| S | <0.05 | |

| P | <0.05 | |

| Hardness | GP | 46-50 |

| GL | 56-60 | |

| GH | 63-65 | |

| Density | ≥7.40 g/cm3 | |

Different chemistries will lead to different operating results, depending on the size and hardness of the grit. DDTC as a primary steel grit supplier, multiple chemistries of steel grit are available. DSGAC that is formulated as a softer (40-50 HRC) metal will round off rapidly, making it ideal for quick stripping of oxides and cleaning of molds. Harder steel grit (55-65 HRC) will maintain the angular nature of the grit to provide continuous cutting action.

| Finish Produced | Approximate Size | Grit Size |

| Deep etch rough | 0.055" | G-14 |

| 0.046" | G-16 | |

| 0.039" | G-18 | |

| Sharp etch | 0.023" | G-25 |

| 0.021" | G-32 | |

| Medium etch | 0.017" | G-40 |

| 0.011" | G-50 | |

| 0.007" | G-80 |

Luoyang Dan Ding Import And Export Trading Co.,Ltd

Room 7 - 2001, Shen-Tai New Century Plaza, Jiu Du Street,Luo Yang,471000,China.

Tel.: (86) 379 6222 3799 Fax : (86) 379 6222 3799

E-mail: info@lyddtc.com.